Monitorovanie podmienok

pre prediktívnu údržbu

V prípade MONITOROVANIA PODMIENOK sa údaje o jazde a stave zaznamenávajú pravidelne alebo nepretržite, aby sa optimalizovala prevádzková bezpečnosť a účinnosť strojov a zariadení. MONITOROVANIE PODMIENOK môže poskytnúť hlavné informácie pre PREDIKTÍVNU ÚDRŽBU. Cieľom je proaktívna údržba strojov a zariadení, zníženie prestojov a zvýšenie efektívnosti celého závodu.

The intelligent drive with condition monitoring for predictive maintenance

The INDUSTRIAL INTERNET of THINGS (IIoT) focuses on internet usage in industrial processes and procedures. IIoT aims at increasing the operational efficiency, reducing costs and speeding up processes. Sensors and sensor data playing a central role provide the basis for CONDITION MONITORING and PREDICTIVE MAINTENANCE.

- Condition monitoring solutions for predictive maintenance systems integrated into the frequency inverter

- System is IIoT/Industry 4.0 READY!

- Available for decentralised and control cabinet solutions

Sensors

- Virtual sensors – the PLC can calculate information such as the optimal oil change time

- Interface for digital/analogue sensors

Communication interfaces

Threshold values or general status information can be communicated externally (via normal Industrial Ethernet dialects)

Integrated PLC

- Local pre-processing of data with the integrated PLC

- Pre-processing of threshold values

Information from condition monitoring can be transferred to predictive maintenance.

Drive-based approach

- Sensorless determination of the optimal oil change time based on virtual oil temperature

- Pre-processing of drive data in the integrated PLC

- Offering the data to the customer via all common interfaces

- Gear unit parameters and specific operational parameters make it possible to precisely calculate the oil change time.

- The NORD solution is based on the fact that the oil temperature is a key factor for oil ageing in gear units.

- A hardware temperature sensor is not needed because virtual sensors calculate the current oil temperature continuously by way of drive-specific parameters.

- The existing frequency inverter from NORD is used as an evaluation unit: The algorithm runs in the internal PLC.

NORDCON APP

Dashboard-based visualisation for drive monitoring and fault diagnosis, Parameterisation with Help function and rapid access to parameters, Oscilloscope function

more information

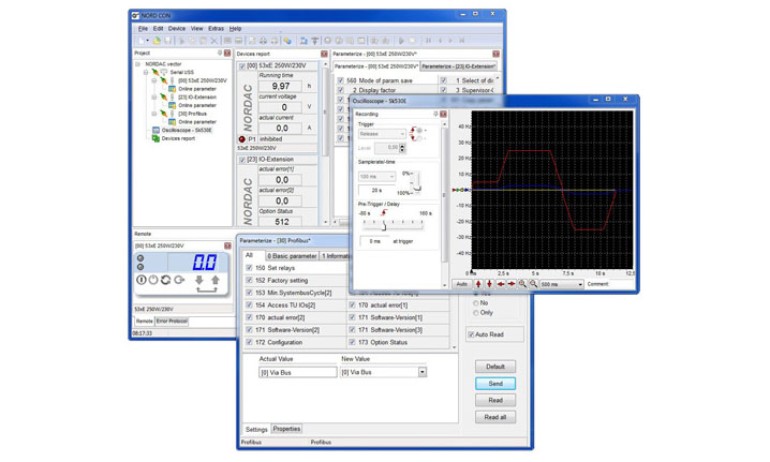

NORDCON SOFTWARE

User-friendly parameterisation and programming of several drives, PLC editor according to IEC 61131-3, supporting Structured Text (ST), Instruction List (IL) and PLCopen Motion Control library

Download NORDCON