Reduce Your Total Cost of Ownership

Our goal is to reduce the Total Cost of Ownership (TCO). These include all costs associated with the purchase, operation, and recycling of a drive system. By using highly efficient technology in combination with a consistent version reduction and standardization, a significant optimization of life cycle costs is possible. NORD® offers a wide range of innovative products and services, assisting you in reducing your system’s total cost of ownership.

The NORD® modular system makes a customized reduction of versions possible at the time of purchase. With the help of efficient drive solutions from NORD®, energy costs incurred can then be reduced significantly.

Get Advice Now

Download White Paper

Get all the information you need about Total Cost of Ownership (TCO) in this NORD White Paper - from different costs, possibilities for optimization and how NORD implements TCO reduction.

Download Our TCO White PaperComplete Drive Optimization From a Single Source

Cost Reduction

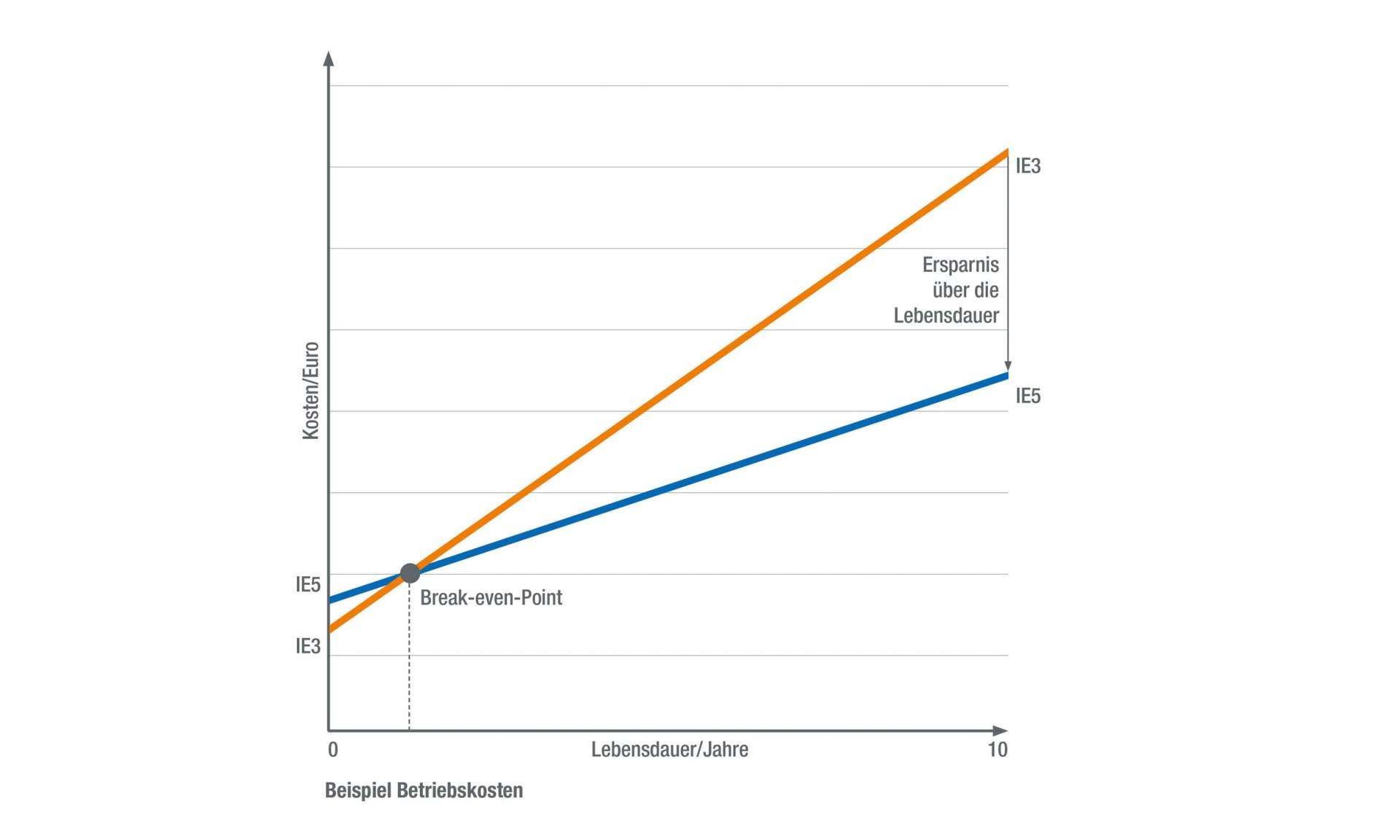

85% of a drive’s life cycle costs are incurred during operation: Energy costs, administrative costs, service and maintenance costs, training and documentation, personnel costs, spare part stocking as well as failures and downtimes but also costs for recycling and disposal. Aspects like energy efficiency, operational reliability, maintenance costs, and version reduction are therefore essential for TCO optimization. The long service life and the low maintenance of NORD® drive systems also have an especially positive impact on the reduction of the Total Cost of Ownership.

NORD® Supports You with Expert Advice

- Evaluation of savings potential

- Efficiency increase of your system

- Reduction of CO2 emissions

- Reduction of service and maintenance costs

- Reduction of drive versions

NORD® Drive Technology Optimizes TCO

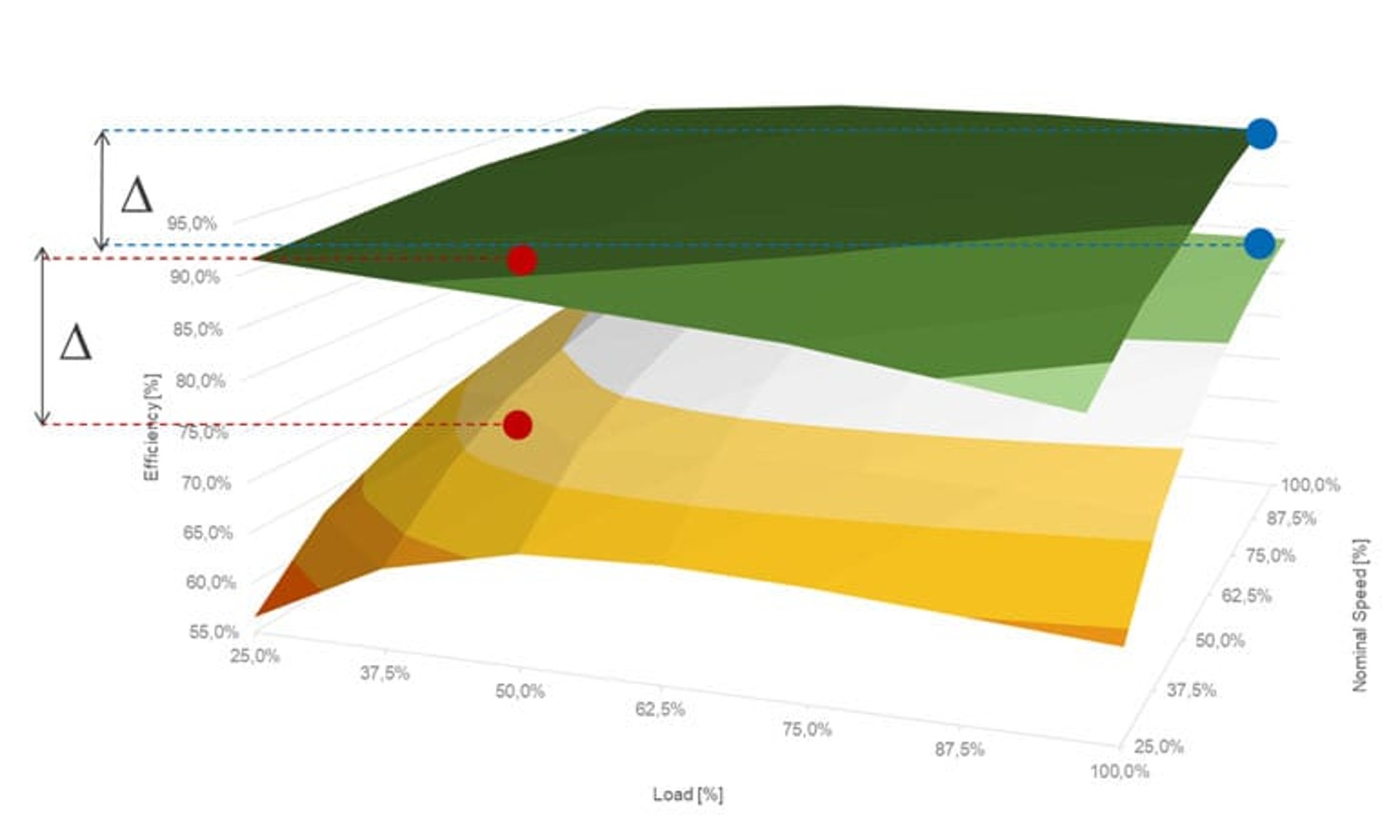

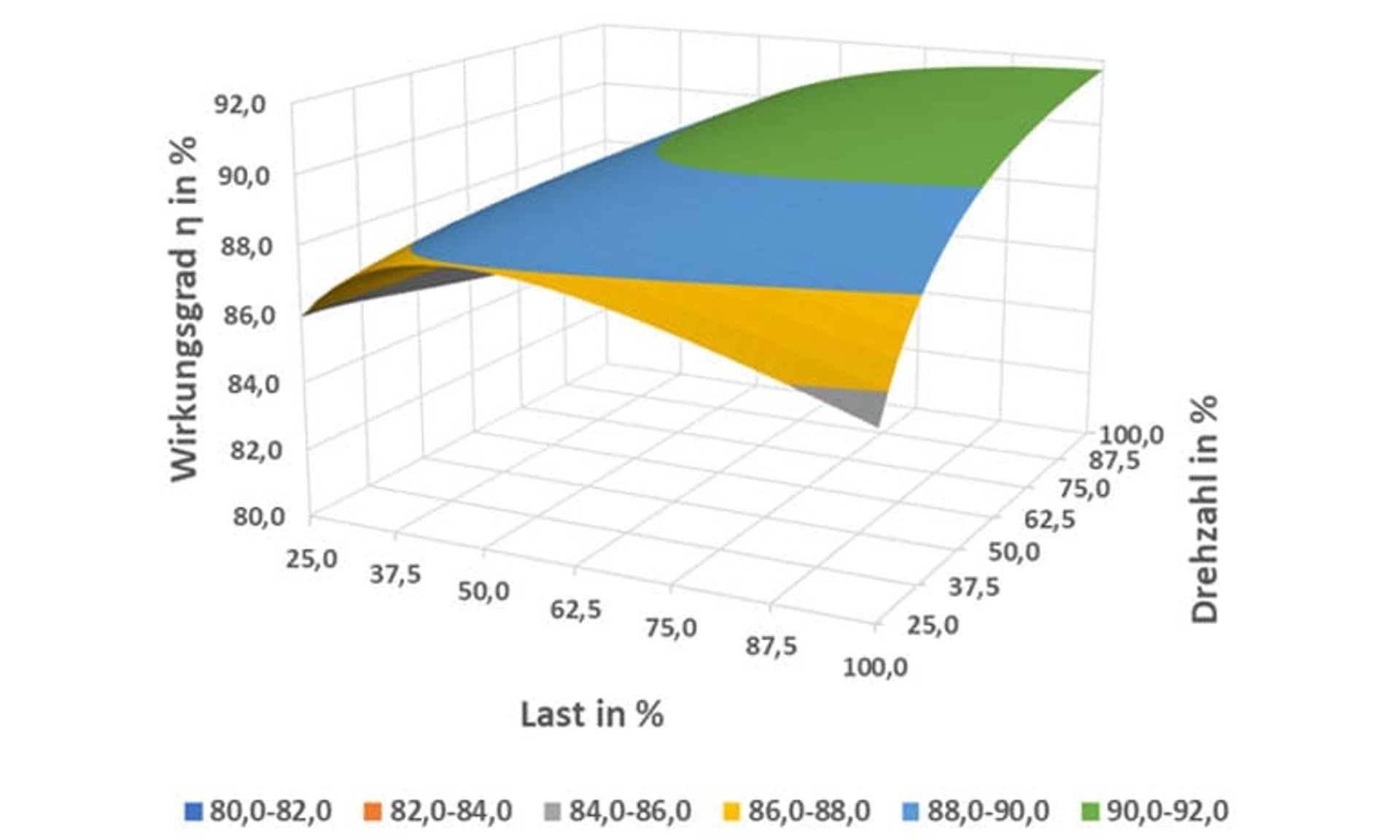

A most effective measure for reducing the Total Cost of Ownership is the use of highly effective synchronous motors. Developed by NORD®, these motors have an efficiency class that is sometimes even better than IE5. The current standard in Europe is efficiency class IE3.

Synchronous motors reveal their full potential in applications with a partial load range and low speed ranges. Systems such as baggage handling and post and parcel processing can achieve significant cost savings through the use of synchronous motors. High cost reductions are achieved over the entire product life cycle.

Save Energy, Optimize Costs

- Through NORD® electric motors that are significantly more efficient than the standard (up to IE5+)

- Through geared motors with high efficiency levels and excellent overload capability

- Through frequency inverters with energy-saving function for partial load and partial torque ranges

- Together, this results in a rapid Return of Investment (ROI)

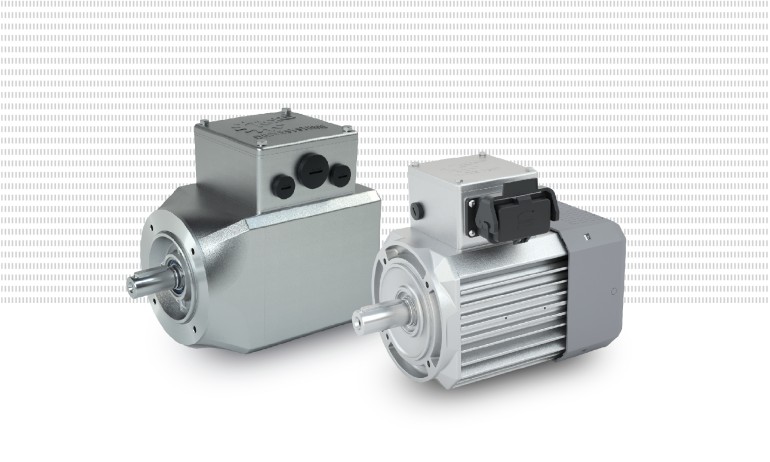

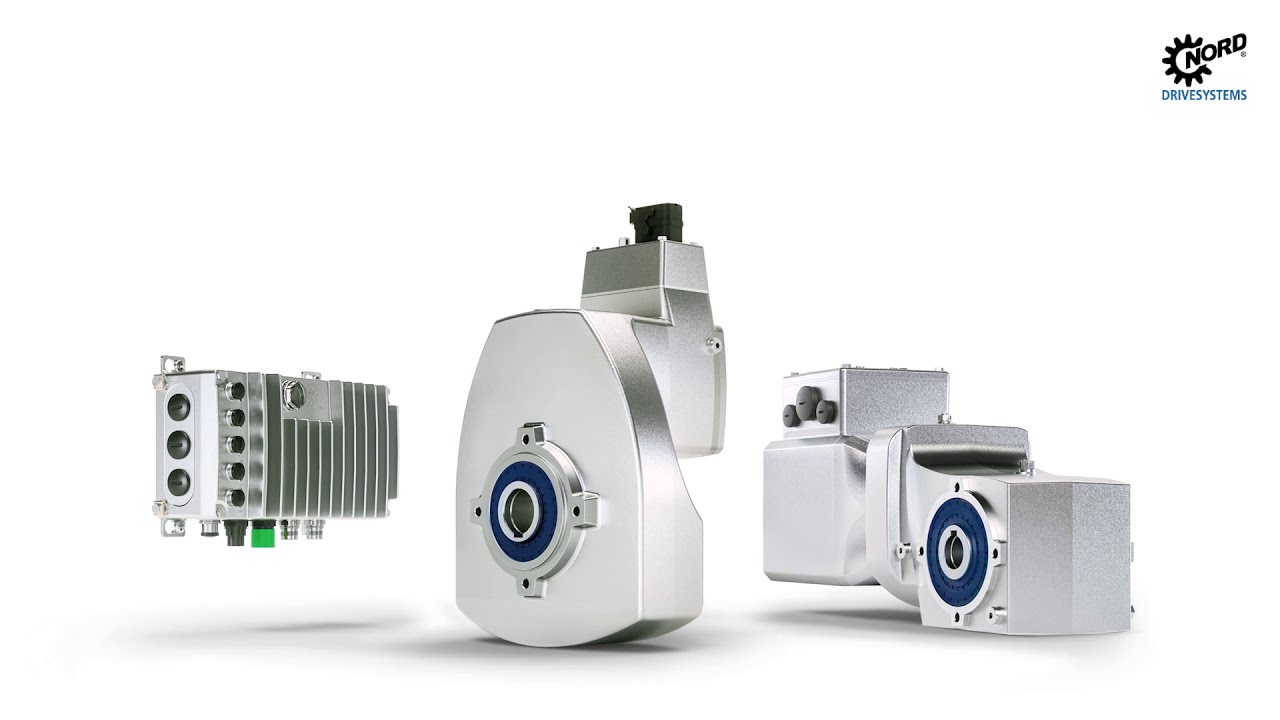

Our New High-Efficiency Portfolio

We developed our high-efficiency portfolio with focus on highest energy efficiency, maximum power density, and the best possible user-friendliness. It consists of the patented DuoDrive geared motor, the integrated IE5+ synchronous motor, and the NORDAC ON frequency inverter. It is the ideal solution for reducing the Total Cost of Ownership.

Reduction of Versions and Standardization

A reduction of versions aims to provide an economically viable coverage of the required speeds and torques within a system, using a minimum of different drive versions. It holds the second largest savings potential over the entire life cycle after energy costs. By way of a targeted reduction of versions, it is possible to minimize administrative expenses and to set up leaner logistics, storage, and service processes. There is a conflict of goals between the conflicting areas of energy efficiency and version reduction. The better the efficiency of an electric motor, even beyond the nominal power, the greater the possibilities for the reduction of versions. NORD DRIVESYSTEMS® has a suitable modular system, the relevant expertise, and extensive experience.

NORD® ECO: Individual Analysis of Your Applications

Would you like to know what savings potential your system offers and how you can best increase efficiency? Our NORD® ECO service analyses your installed drives on site with regard to energy efficiency, dimensioning, and number of versions and creates a tailor-made drive concept for your applications to reduce life cycle costs.

Contact Your Personal TCO Consultant from NORD® Now: