Lenzing AG

Reliable Pump Drives for Sustainable Fibers

Customer Profile

Over the 85 years since it was established in Austria, Lenzing AG has built up a reputation as a global market, technology and sustainability leader in the field of fiber production. The sustainably produced high-quality fibers of the Lenzing brands TENCEL™, VEOCEL™, etc. are the raw material for many textile and non-woven fabric applications. Being a pioneer of the ecological movement, the company had already established their first environmental department in 1975, and began restructuring their manufacturing towards resource-saving production.

Project Requirements

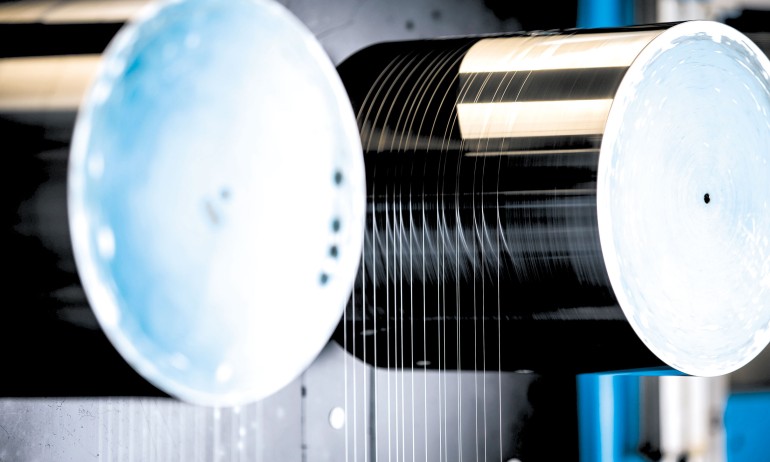

Fibers from Lenzing are used for different textile and non-woven fabric applications, for protective and work clothing, and for a wide range of industrial applications. The fiber production process converts raw wood material into a liquid mass. With the aid of purpose-built spinning pumps, the material is pressed through fine nozzles to form threads. The exact procedure is a trade secret closely guarded by Lenzing.

As these threads are endless and need to have a constant denier, the pump drives must supply a reliable and constant performance. Lenzing AG’s further requirements for their pump drives include:

- Constant speed without encoder feedback

- Temperature resistance up to 60 °C

- Extensive freedom from maintenance

- Particularly important for the ecologically committed company – excellent energy efficiency

The Project at a Glance

For the high-precision operation of their spinning pumps, the fiber manufacturer Lenzing relies on IE5+ synchronous motors in the smooth-surface and fanless version. They are combined with two-stage NORDBLOC.1<sup>®</sup> helical in-line gear units.

- Efficiencies of up to 95%

- Temperature resistance up to 60 °C

- Constant speed without encoder feedback

- Resistance to chemicals

Application Solution

Together with Lenzing, NORD specialists developed a drive solution consisting of IE5+ synchronous motors and ideally matched two-stage NORDBLOC.1<sup>®</sup> helical in-line gear units. IE5+ motors provide a constant torque over a very wide speed range and thus achieve efficiencies of up to 95 percent, surpassing the highest defined efficiency class IE5.

IE5+ motors from NORD offer extremely high operational reliability. Designed as Interior Permanent Magnet (IPM) motors, the magnets are incorporated into the rotor, significantly increasing reliability and safety. Furthermore, permanent magnets in IPMs are better protected against current peaks, which can occur with high currents that may generate an opposing field. The IE5+ motor in the smooth-surface and fanless version also handles temperatures of 60 °C and is also resistant to chemicals used during production.

The motor plug was specially designed for Lenzing. In the individual customer solution, the connection cable is not fed to the motor’s terminal board via a PG screw connection, but is directly connected to the terminal box. In case of a replacement, this allows for a quick electrical connection and disconnection of the motor. Potential downtimes will be reduced, which is an important factor for the customer.

IE5+ synchronous motors (TENV)

Efficient. Hygienic. Compact

IE5+ synchronous motors (TEFC)

Efficient and Compact

More Information