- Versatile

- Durable

- Modular

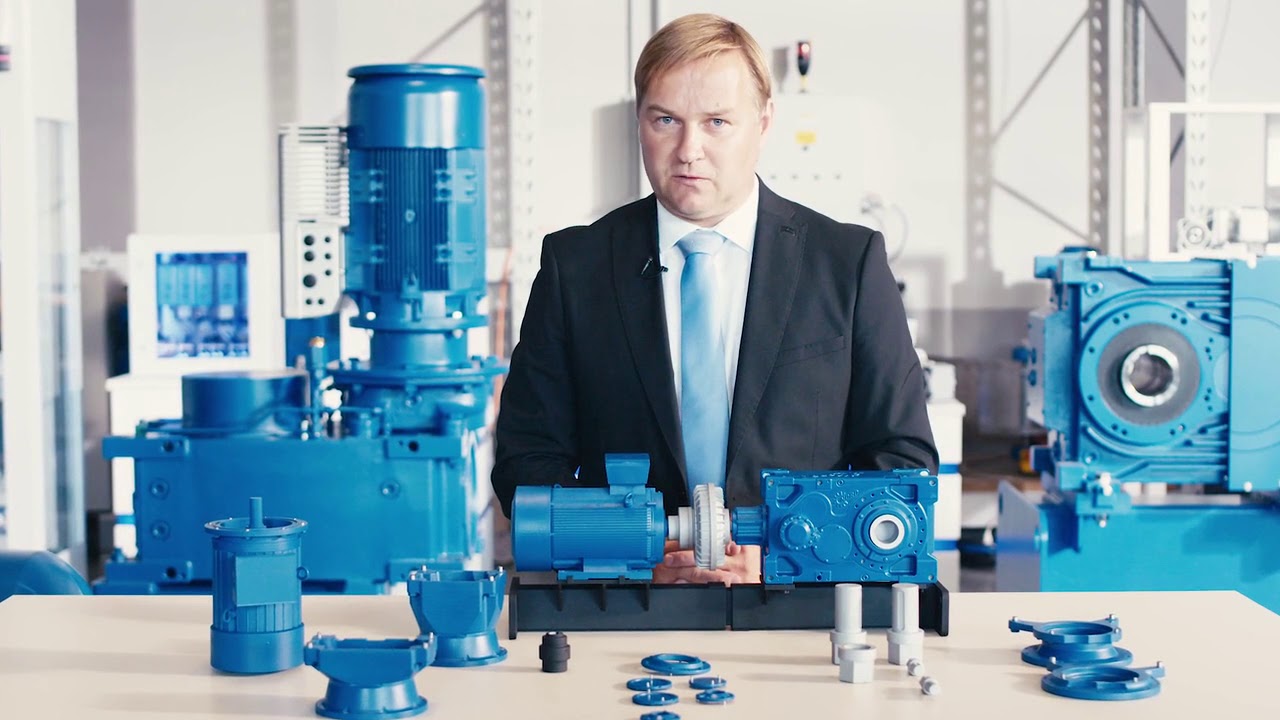

MAXXDRIVE® Industrial Gear Units

Extremely high output torques, quiet operation and a long service life: These are the outstanding features of the industrial gear units from NORD DRIVESYSTEMS in a one-piece UNICASE™ housing.

Our MAXXDRIVE<sup>®</sup> industrial gear units provide high output torques from 15,000 to 282,000 Nm and are perfect for use in heavy-duty applications such as agitators, belt drives, mixers, mills, and bucket elevators.

By using the proven UNICASE™ housing concept, our MAXXDRIVE® industrial gear units offer high load capacities paired with a reduced risk of leakage.

The right-angle gear units can easily withstand the harsh conditions of use on the conveyor belt.

Learn About IGUs in Bulk Goods Handling

Are you interested in our MAXXDRIVE<sup>®</sup> portfolio? Our specialists are always at your disposal and offer valuable advice on your requirements.

Contact Us Today

MAXXDRIVE<sup>®</sup> industrial gear units are available as parallel gear units or right-angle gear units. They are installed in the one-piece UNICASE™ housing and can accommodate large roller bearings, which guarantee a long service life. NORD is the industrial gear unit manufacturer with the world's largest industrial gear units in a UNICASE™ housing.

Find out more about the complete MAXXDRIVE<sup>®</sup> portfolio and its advantages for your application.

Watch Video

The new MAXXDRIVE<sup>®</sup> XD from NORD combines proven MAXXDRIVE<sup>®</sup> components with a geometrically optimized one-piece housing that has been specially designed for high loads. The extended center distance replaces the use of oversized gear units, which reduces the weight of the gear units used by 60%. The newest supplement of our industrial gear units is also equipped with an inspection cover allowing for a simple and easy inspection of internal components.

With the development of the new MAXXDRIVE<sup>®</sup> XD series, NORD completes its proven range of MAXXDRIVE<sup>®</sup> industrial gear units engineered specifically for lifting gear applications.

MAXXDRIVE<sup>®</sup> XD

Please note our privacy statement.

NORD keeps you connected with industry news, insider info, and exclusive insight from our technical experts. Subscribe to our monthly newsletter to receive this valuable information!

Sign Up Now