NXD Surface Solutions from NORD

Surface Protection for Extreme Conditions

NORD's NXD surface treatment creates easy-to-clean surfaces that stand up to tough environments. Drives treated with the NXD surface treatment are reliable and durable, even in the most demanding ambient conditions.

Download FlyerConstant Protection with NXD BASIC® and NXD tupH®

NORD's NXD surface treatment has been specifically developed for aluminum. Made up of a galvanically produced base layer, this surface treatment makes aluminum surfaces corrosion-resistant. Not only does it reveal the strengths of aluminum components for demanding installations, it offers two variants for optimum protection of your drive solution.

NXD BASIC®

NXD BASIC® can be used for protection of standard varnishes if the current varnish isn't sufficient.

How It Works:

First, the aluminum housing is fully coated with a galvanically produced base layer. Then, treated components are mounted and coated with a highly adhesive varnish.

Advantages:

- Safe protection against scratches – even in cases of damaged varnish

- Corrosion-resistant according to the highest corrosion class, C5

- Customer-specific colouring possible

Common Applications:

- Water treatment

- Car wash facilities

- Shipping

- Offshore installations

Benefits:

Durable drive solutions

Reliable operation

Secure choice

20,000,000 standard configuration options

NXD tupH®

NXD tupH® is the surface protection for extreme conditions in wash-down applications.

How It Works:

In a first step, the aluminium housing is fully coated with the galvanically produced base layer. It is then coated with a thin high-performance sealer.

Advantages:

- Resistant to acids and alkalis

- No blistering, flaking or microcracks

- Non-porous surface

- Corrosion-resistant according to the highest corrosion class C5

- Food-safe according to FDA and EU Regulation 1935/2004

Common Applications:

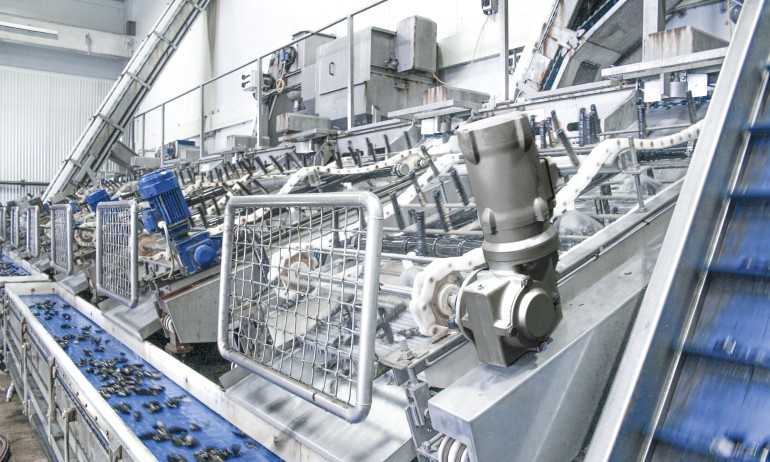

- Food & Beverage

- Dairies

- Fish & Seafood

- Pharmaceuticals

Benefits:

- High level of hygiene

- Quick cleaning

- Cost efficiency

- Durable drive solutions

- Operational reliability

- Investment security

- Wide variety of NORD modular products

"NXD’s previous generation, NSD, has already impressively demonstrated its resistance as an effective protection for aluminum surfaces in practice. Drives that previously had to be replaced regularly, serve well for years now, thanks to this technology. We are permanently focused on our customers’ industries and are continuously developing the protection systems. Surfaces treated with NXD tupH® are thus free from chromates and PFAS. This increases the investment security for our users."

Take The Test

Interested? Get a free flyer with a sample of our surface solutions!

Order free sample nowSuccessfully Tested:

|

|

|

|

|

|

|

|

|

Surface Protection for NORD Drives

Drives with aluminium surfaces are equipped with NXD BASIC® or NXD tupH®. Find out here, which ones they are. We create your tailor-made drive solution with high surface protection, including project-oriented advice, high availability, short delivery times and quick service.