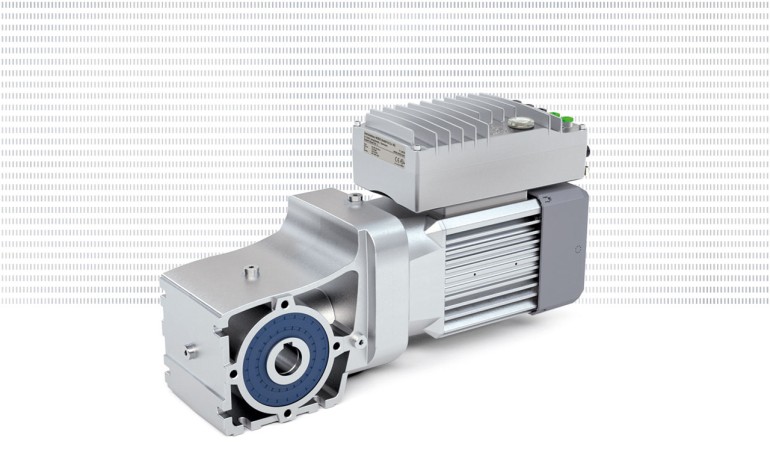

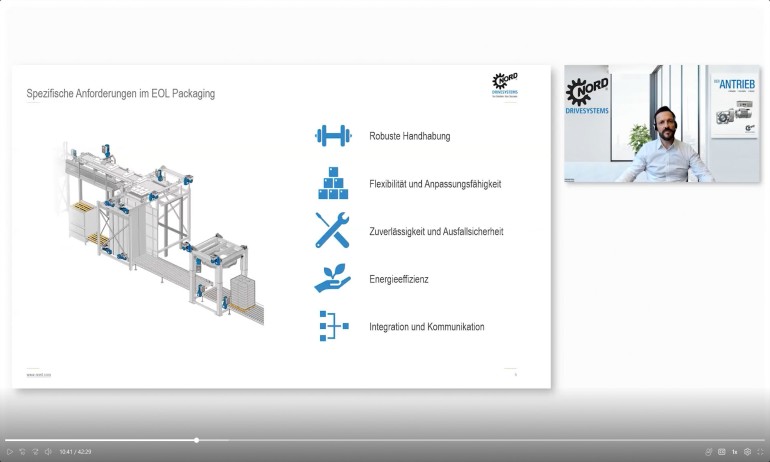

Oversized servo systems are commonly used in end-of-line packaging, which require centralised control units in the control cabinet. NORD DRIVESYSTEMS offers reliable, economic and lean plug-and-play drive solutions that can be decentrally controlled to meet the packaging industry’s demanding requirements for precision and dynamics.

Find out more in our webinar